Transform CX with AI at the core of every interaction

Unify fragmented interactions across 30+ voice, social and digital channels with an AI-native customer experience platform. Deliver consistent, extraordinary brand experiences at scale.

Agentic AI for Manufacturing: Use Cases and Examples

For years, blue-collar operations in manufacturing seemed like the last place where artificial intelligence could play a meaningful role. That changed when AI agents entered the picture. Leading manufacturers are now adopting agentic AI in manufacturing plants to move from rigid, rule-based machinery to autonomous, self-directing factory systems.

Gartner’s 2026 strategic technology trends underscore this shift, highlighting human-machine collaboration as a defining theme. Agentic AI in the manufacturing industry also reshapes customer experience through predictive maintenance, proactive service, and faster support cycles.

Continue reading to explore the applications of agentic AI in manufacturing, including its benefits, challenges, and real-world business examples that demonstrate what this shift looks like in practice.

What is agentic AI in manufacturing?

Agentic AI refers to intelligent systems that can think, plan, and act independently. They do this using advanced models, real-time data, and built-in reasoning abilities.

In manufacturing, this means an AI system can understand an operational goal, break it into tasks, decide the best path, and execute it without waiting for step-by-step instructions. It can also learn from new situations and improve its next action.

How is agentic AI in manufacturing different from traditional automation and predictive AI?

Capability | Agentic AI | Traditional Automation | Predictive AI |

Objective | Achieve a goal through self-directed planning, for example, planning an entire welding sequence when machine load changes | Follow fixed instructions and workflows, such as repeating the same pick-and-place movement | Predict what may happen using data patterns, like forecasting machine failure based on vibration data |

Decision-making | Chooses actions based on context and reasoning because it evaluates multiple variables and current shop-floor conditions | Executes predefined rules without interpretation because it depends on logic coded by engineers | Gives probability-based predictions such as demand spikes or downtime risk |

Adaptability | Adjusts to new conditions in real time, for example, rerouting tasks when a station goes offline | Struggles with change unless reprogrammed because behavior is locked into fixed rules | Learns trends but cannot adjust operations on its own |

Autonomy | Can operate and improve with minimal supervision, for example, triggering maintenance and completing the workflow end-to-end | Needs human-defined triggers because it cannot identify new goals on its own | Needs humans to act on predictions since it cannot execute |

Value for manufacturing | Handles complex scenarios like coordinating multi-step workflows across teams | Performs repetitive structured tasks with consistency | Helps teams plan ahead by predicting likely issues |

The agentic AI manufacturing market, according to Mordor Intelligence, is valued at USD 5.5 billion in 2025 and is projected to reach USD 16.79 billion by 2030, growing at a CAGR of 25.01%.

The broader agentic AI market is projected to reach USD 93.20 billion by 2032. This proves that agentic AI is expanding beyond production and now influences the supply chain, service, and after-sales operations.

A real-world look at Boeing’s shift toward AI-powered manufacturing

Boeing manages one of the world’s most complex production environments, and traditional automation alone could not keep up with design changes and quality needs. The company introduced AI-driven inspections, digital twins for models such as the 787 Dreamliner and automated assembly systems that adapt to real-time conditions. This reduced defects, improved consistency and cut assembly times nearly in half.

Bonus Read: Agentic AI vs. traditional AI: Key differences, use cases and adoption framework

Key benefits of agentic AI in manufacturing

The International Data Corporation’s (IDC’s) 2026 Manufacturing FutureScape outlines how agentic AI is creating measurable improvements for factories worldwide. These findings help manufacturing leaders understand where the next wave of operational gains will come from.

Factories adapt faster to changing production needs

Factories still rely on control systems that need manual setup and constant engineering time. Agentic AI shifts this model by enabling software-defined operations that adjust to new requirements with minimal effort. IDC expects that by 2029, 30% of factories will configure and manage control systems centrally through open, virtualized, software-defined automation platforms.

True IT and OT connectivity without manual stitching

Most plants struggle with fragmented data. Teams pull information from different systems, which slows down decisions and limits visibility. IDC predicts that by 2027, 40% of all operational data will be integrated across applications and platforms autonomously through standardization and AI agents specifically designed for various data types. This will enable manufacturing plants to act on a single, consistent source of truth, reducing delays on the shop floor.

Autonomous operations that handle rising complexity

Manufacturers cannot easily scale their output or launch new product lines when their operations are tied to rigid equipment logic. Agentic AI creates a flexible environment in which processes can be centrally updated and executed consistently across the plant. IDC notes that by 2029, nearly one-third of factories will operate on software-defined automation, enabling operations to adapt more quickly.

Better human and robot collaboration that protects efficiency

Manufacturing plants deploy robots without creating closed skill loops between workers and machines. This leads to longer downtime, higher retraining costs, and workflows that break when something changes. Agentic AI facilitates this by creating adaptive training loops between human tasks and robotic behavior, enabling both parties to learn and adjust in real-time. IDC estimates that firms that ignore these closed human-robot skill loops will face 20% higher downtime and retraining costs by 2028 compared with peers that build bidirectional training systems.

Agentic AI in manufacturing operations: 5 real use cases

Deloitte’s 2025 survey of 600 manufacturing executives shows that 78% of manufacturers now allocate more than 20% of their improvement budget to smart manufacturing. Another 88% expect these investments to increase or remain steady in the coming year. This makes it essential to understand the most practical and high-impact agentic AI use cases in modern plants.

Predictive and prescriptive maintenance on critical assets

Many plants still rely on manual checks or basic rules to detect equipment problems. Failures often appear without warning and shut down entire lines.

For example, a critical pump or motor can fail overnight, stopping production for hours while technicians scramble to diagnose the issue and locate replacement parts.

How agentic AI helps with predictive and prescriptive maintenance

- It monitors live sensor signals and historical patterns to detect early signs of failure and alert teams before the asset breaks.

- Recommends the next best action by analyzing severity, workload, and part availability, allowing planners to schedule repairs at the optimal moment.

- Prepares the maintenance workflow by ordering parts, assigning technicians, and updating production schedules to minimize downtime.

A clear example is Ford’s work on predictive maintenance. Ford struggled with extended downtime on its Transit vans because Fuel Injection Equipment failures kept vehicles in service bays for a full day, resulting in operational losses for commercial fleet customers.

The company developed an AI model that utilized connected vehicle data to predict fault days in advance. This allowed technicians to prepare parts and schedule preemptive service. The system predicted 22% of failures 10 days in advance, with a low false-positive rate. Service time was reduced from 24 hours to 3 hours, resulting in more than 100,000 hours of downtime saved and creating millions of dollars in value for Ford and its fleet customers.

Dynamic production scheduling and line changeovers

Production schedules often break when demand shifts or when a line experiences unplanned delays. Teams then spend hours reshuffling batches, reallocating resources, and coordinating with suppliers.

This slows output and increases the risk of stockouts or excess inventory, especially when plants run multiple product variants under tight deadlines.

How agentic AI helps with dynamic production scheduling:

- It analyzes live demand signals, machine status, labor availability, and inventory levels to generate the best possible production sequence.

- Detects upcoming bottlenecks and adjusts schedules to maintain balanced lines and prevent unexpected production stops.

- Automates changeovers by preparing instructions, optimizing material flow and guiding teams through the quickest setup steps.

Nestlé’s work in automated planning shares some great insights here. They faced a complex scheduling challenge across their global operations due to shifting demand, strict production deadlines and logistics constraints.

The company deployed AI models that used sales trends, real-time conditions, and supplier performance data to forecast demand and optimize production runs. This reduced forecasting errors by 30%, improved supply chain resilience and helped cut facility downtime by up to 15% while increasing labor productivity through more predictable planning.

Recommended watch:

Autonomous quality inspection and end-to-end traceability

Quality teams often rely on manual inspection to detect defects on fast-moving production lines. This creates inconsistency because human accuracy tends to drop at high speeds and across long shifts.

Minor flaws slip through, leading to rework, scrap, warranty claims, and customer dissatisfaction. This becomes even harder when products involve microscopic components or fragile materials.

How agentic AI helps with autonomous quality inspection:

- It uses AI vision models to detect defects in real-time, even at speeds where human inspection cannot keep up.

- Flags anomalies and isolates suspect batches so teams can trace the issue back to the exact station and prevent repeat errors.

- Maintains consistent inspection quality without fatigue, shift changes, or variability in human skill.

Panasonic’s LCD manufacturing lines show how this works in practice. The company struggled with slow, inconsistent manual checks for mounting conditions and microscopic flaws in LCD and OLED panels.

Panasonic deployed AI-based visual inspection systems built on deep convolutional neural networks to automate defect detection at scale. The machines now run continuously with high accuracy, identifying issues that human inspectors often miss and transforming the quality assurance workflow across major production facilities.

End-to-end supply and material coordination with agents

Most manufacturing plants continue to experience supply disruptions because information moves slowly between procurement, suppliers, logistics teams, and production planners. A delay in one area can lead to stockouts or excess inventory. When market demand changes, teams rush to adjust orders and reroute shipments, which raises costs and reduces reliability.

How agentic AI helps with supply and material coordination

- It connects suppliers, procurement teams, logistics partners, and production lines via autonomous agents that update each other in real time.

- It automatically adjusts orders, shipment routes, and delivery schedules when demand shifts or supply risks arise.

- It provides planners with a comprehensive view of material flow, enabling them to prevent shortages, reduce inventory costs, and respond more quickly to disruptions.

There’s no real-world example for this use case; yet, think of a food production company that faced market volatility, making wholesale and procurement processes hard to manage, especially amid changing demand and logistics constraints. They could deploy a multi-agent system in which different agents represented suppliers, wholesalers, retailers, and logistics providers.

These agents could monitor sales trends and supplier data to adjust orders and reroute shipments automatically. This could improve visibility across the supply chain, reduce planning costs, prevent stockouts, and create smoother coordination between suppliers and retailers.

Shop-floor co-pilots for workers, safety and standard work

Operators often lose valuable time trying to interpret complex machine errors. Many codes require deep technical knowledge, so teams wait for specialists to diagnose the issue.

This slows production, increases downtime, and creates training gaps for new workers who are unable to troubleshoot independently.

How agentic AI helps with shop floor copilots

- It translates machine errors into clear language, so operators understand the issue immediately.

- Recommends solutions based on asset history, documentation, and past resolutions, enabling workers to act without waiting for experts.

- Automates routine tasks and guides new employees with simple step-by-step instructions that improve safety and consistency.

Siemens shows how this works on the shop floor. At its Erlangen electronics factory, Siemens deployed an Industrial Copilot that converts machine error codes into natural language and suggests fixes based on operational history.

The system operates on local NVIDIA-powered infrastructure to ensure data security. Operators now resolve issues faster, reduce bottlenecks, and train more effectively through interactive guidance. A dedicated Shop Floor Worker Copilot is planned for release by the end of 2025 to extend these capabilities further.

We’re exploring agentic AI in our manufacturing plant to act, not just alert. Which shop-floor tasks can it own end-to-end this year?

Agentic AI has evolved sufficiently to fully handle tasks such as monitoring asset health, triggering work orders, orchestrating line changeovers, running AI vision checks and coordinating material calls from supermarkets to lines. It can also translate machine errors, suggest fixes, log actions, and update MES or maintenance systems, while your human executives supervise exceptions and process changes.

Challenges and considerations in implementing agentic AI in manufacturing

Even with major brands reworking their manufacturing processes with agentic AI, there are real implementation hurdles that you must understand before diving in.

Getting teams to trust autonomous agents

According to the World Economic Forum’s June 2025 report, one of the significant barriers to the adoption of AI agents is trust. The report states: “Trust remains a key barrier, as many teams are hesitant to rely on autonomous systems without clear evidence of their capabilities and limitations.”

Tips to tackle this challenge

- Engage operators and engineers early through controlled pilots that demonstrate clear value.

- Build human-agent collaboration first, rather than full autonomy, to increase confidence.

- Secure executive sponsorship and define transparent success metrics to measure trust.

Integration complexity and legacy systems

A systematic review of AI adoption in production reveals that adoption remains limited due to system integration, data-related issues, workforce concerns, and the need to ensure trustworthy AI. Many plants use a mix of machines, data silos, and legacy IT/OT systems, which makes integration challenging.

Tips to handle this challenge

- Audit machines, control systems, data sources, and legacy constraints before committing to large rollouts.

- Start with a single line or cell and phase the implementation once data and connectivity gaps are evident.

- Build a data fabric foundation instead of forcing agents into fragmented environments.

Ensuring ethical accountability and governance

Agents influence production, safety, staffing, and supplier decisions. Without accountable oversight, you risk liability, worker pushback, or regulatory concerns.

How to tackle this

- Define ownership for every agent action and set clear escalation paths.

- Build human review steps for critical decisions and maintain transparent logs.

- Establish an audit mechanism to enable leadership to understand how and why an agent acted.

Internal skills, motivation and external dependencies

UK government research notes that internal factors, such as skills, motivation, and resource availability, as well as external factors such as suppliers and market volatility, influence the success of adoption.

How to be prepared for this

- Develop internal skills through targeted training, clear roles, and structured change management processes.

- Map external dependencies, including supplier data quality and logistics variability.

- Treat agentic AI as a system-wide program rather than a single software installation.

Adopt digital automation as the first steppingstone towards agentic manufacturing

The scale and complexity of manufacturing vary widely across businesses. Some run high-volume lines. Others manage diverse product mixes. Regardless of the setup, it is risky to transition directly to full plant-wide autonomy without first demonstrating value in a controlled environment.

A practical starting point is to deploy customizable, enterprise-grade AI agents that handle digital operational tasks and consistently track manufacturing activities. Soon (between 2027 and 2030), these same agents can support more advanced scenarios. They can help create autonomous planning loops that connect production, maintenance, and logistics. Digital twins can run what-if scenarios in the background to suggest better plans. Multi-agent systems can coordinate workloads across plants in sectors such as automotive and electronics, so leaders see a unified picture of capacity and risk.

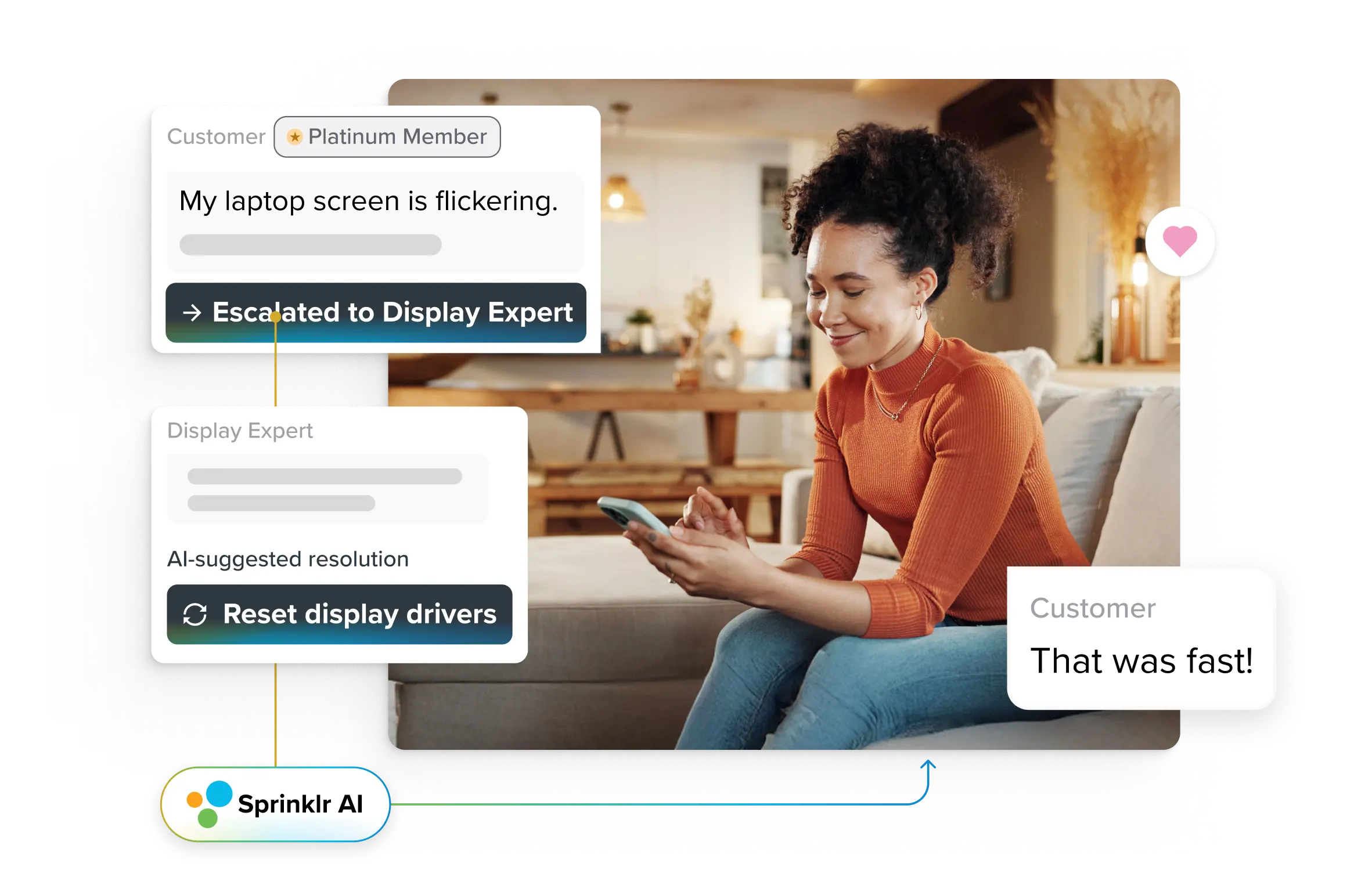

Sprinklr’s AI agents, trusted by global enterprises, can be tailored to your brand’s standards, compliance rules, and service expectations. They help you automate day-to-day digital operations, allowing your teams to focus on preparing for agile automation across heavy-duty production environments.

Book a free demo and our specialists will guide you through a clear, personalized roadmap tailored to your business.

Frequently Asked Questions

Traditional manufacturing automation follows fixed rules. Machines do the same task in the same way until an engineer changes the logic. Agentic AI works toward a goal. It can plan tasks, monitor conditions, and adjust actions when demand, machine health, or constraints change. It also coordinates across systems, such as MES, ERP, quality, and maintenance, rather than being locked inside a single machine or cell.

Agentic AI needs clean, connected data from machines, sensors, quality systems, maintenance logs and business systems. At a minimum, you need reliable time-series data, clear equipment IDs and consistent master data for products, materials and locations.

You also need secure connections between OT systems on the shop floor and IT systems such as ERP and PLM. A clear data ownership model and access controls are essential, so agents can read and act without creating security or compliance issues.

No. Agentic AI shifts the human role instead of removing it. Agents watch machines, suggest actions, adjust schedules, and handle repetitive digital tasks. Humans focus on supervision, exception handling, process improvement, and safety decisions. Plants that treat agentic AI as a partner for operators and engineers, rather than a replacement, achieve better adoption and results.

You need to prove that agents make work safer, simpler, and more predictable. Start with pilots that address visible problems, such as unplanned downtime or poor quality and share precise results with the teams.

Involve operators and supervisors in the design process, seek their feedback, and demonstrate how recommendations are made. Back this with training, clear communication from leadership and a promise that new skills and roles will be developed, not ignored.

Start with one use case that has a clear business impact and strong data, such as predictive maintenance on a critical asset, dynamic scheduling for a single line or AI vision for a high-defect product. Define sharp success metrics, such as reduced downtime, faster changeovers, or fewer customer returns.

Run a contained pilot, harden the process and then extend to adjacent lines or plants. Use each step to build your data foundation, governance and skills for larger, more agile programs.