Transform CX with AI at the core of every interaction

Unify fragmented interactions across 30+ voice, social and digital channels with an AI-native customer experience platform. Deliver consistent, extraordinary brand experiences at scale.

AI Didn’t Fix Supply Chains — Agentic AI Will

When a shipment misses its slot or demand shifts overnight, the impact is immediate —missed SLAs, rising costs, and broken customer promises. Agentic AI in supply chain operations enables you to sense disruptions and act autonomously within defined guardrails, enabling faster, more consistent decision-making than traditional human escalation models.

Unlike predictive tools that stop at recommendations, agentic systems can evaluate trade-offs across cost, service, and inventory in controlled environments, execute targeted changes, and keep stakeholders informed in real-time. The result is fewer manual firefights, faster recovery from disruption, and greater confidence in customer commitments.

According to Gartner, intelligent agents are expected to power a growing share of supply chain platforms by 2030. In the sections ahead, we break down the foundational concepts behind agentic AI, explore eight high-impact supply chain use cases, and outline practical steps you can take to move from experimentation to measurable, production-grade impact.

What is agentic AI in supply chain?

Agentic AI in supply chain refers to autonomous, reasoning-driven AI systems that don’t just analyze operations, but actively manage them. These systems can sense disruptions, evaluate trade-offs, and execute decisions across planning, procurement, logistics, and delivery within predefined business guardrails.

Trained on enterprise data ranging from operational performance and historical outcomes to communication patterns and exception-handling workflows, AI agents learn how supply chain teams actually operate under pressure. They interpret real-time conditions, identify emerging risks, decide on corrective actions, and act while keeping human teams informed of high-impact events that require oversight.

Unlike static automation or rules-based workflows, agentic AI operates with intent. It adapts to changing conditions, navigates complexity across systems and partners, and helps enterprises maintain continuity without constant manual intervention.

Read More: Agentic AI vs. Traditional AI: Key Differences, Use Cases, and Adoption Framework

How an enterprise uses agentic AI to act in real-time

Walmart offers a strong example of how large enterprises are adopting agentic principles in supply chain execution, shifting from static planning to systems that can sense disruptions, evaluate trade-offs, and trigger action in near real-time.

Walmart uses digital twin environments and multi-horizon forecasting models to test replenishment scenarios, simulate trade-offs, and dynamically adjust inventory flows across its network. These systems allow teams to respond faster to demand shifts while minimizing downstream disruption.

To enable real-time decision-making, Walmart also deploys ambient IoT sensors across stores and distribution centers to track inventory movement and maintain cold-chain compliance. This continuous data flow reduces manual scanning, improves inventory accuracy, and enables automated responses, freeing teams to focus on higher-value strategic work.

Agentic AI in supply chain operations: 8 high-impact use cases

Organizations that invest heavily in AI-led supply chain operations report higher revenue growth than peers. The difference lies in execution. Agentic AI translates visibility into autonomous, adaptive action.

Here’s how it creates measurable value across eight core functions:

1. Demand sensing and delta replanning across APS/MRP

One of the hardest parts of running a supply chain is reacting fast enough when demand shifts. Most planning environments still rely on periodic data refreshes and batch-driven Advanced Planning Systems (APS) and Material Requirements Planning (MRP) runs, which means by the time plans are updated, the market has already moved on. The outcome is all too familiar: too much inventory in some places, not enough in others, and production plans that no longer match what customers actually want.

Agentic AI changes that dynamic. It continuously senses demand signals and autonomously triggers delta-based replanning across APS and MRP systems, making targeted adjustments without blowing up the entire plan.

How it works

Step 1: Detects demand shifts early

Agentic AI continuously monitors near-real-time demand signals, including point-of-sale data, order intake, changes in customer backlog, promotional activity, and external factors such as weather forecasts.

For example, when sustained rainfall is forecast across multiple regions, the system identifies early demand acceleration for rain gear and related SKUs before traditional planning cycles reveal the trend.

Step 2: Runs delta-based replans

Rather than triggering a full planning rerun, the agent identifies the smallest set of changes required to stay aligned with demand. It selectively adjusts production quantities, raw material requirements, or distribution plans, minimizing disruption while preventing overreaction that often fuels the bullwhip effect.

Step 3: Simulates trade-offs in a controlled environment

Before execution, the agent evaluates alternative responses using a digital twin or simulation layer. It weighs trade-offs across service levels, cost, lead times, and capacity constraints, ensuring that the proposed change improves outcomes without introducing downstream risk.

Step 4: Executes autonomously with human oversight

Once validated, the agent updates APS and MRP systems in near real-time, triggering purchase orders, adjusting production schedules, or rebalancing inventory flows. Human planners are notified only when decisions exceed predefined thresholds or require judgment-based intervention.

Through this continuous sense – decide – act loop, agentic AI helps enterprises reduce overproduction, stabilize inventory positions, and ensure products reach the right markets at the right time without relying on constant manual replanning.

2. Smart transport sourcing and mid-day re-tendering

Logistics teams operate in a constant state of variability — vehicle breakdowns, port congestion, labor shortages, and sudden carrier unavailability are routine, not exceptions. When a tender fails mid-day, the response is often reactive: planners scramble to reissue bids, accept premium rates, or manually intervene across systems to keep shipments moving.

This approach is costly, error-prone, and difficult to scale.

Agentic AI in supply chain logistics introduces autonomous, real-time transport sourcing, allowing you to dynamically re-tender shipments and rebalance carrier allocation without disrupting downstream execution.

How it works

Step 1: Monitors transport execution in real-time

The agent continuously tracks shipment execution signals — carrier acceptances, GPS events, ETA deviations, dwell times, and exception alerts — through the Transportation Management System (TMS). When a high-priority load shows early risk indicators, such as a delayed pickup or carrier non-response, the agent proactively opens a controlled re-tender window.

Step 2: Runs contextual, load-level re-tenders

Rather than reissuing broad tenders, the agent targets only the affected loads. It ensures no duplicate shipments or conflicting carrier commitments are created, while ranking eligible carriers based on lane performance, contractual rate bands, service reliability, and real-time capacity signals — reducing unnecessary premium freight exposure.

Step 3: Confirms alternate carriers within predefined guardrails

Using pre-approved carrier contracts and rate thresholds, the agent selects the best-fit alternative and automatically confirms the assignment. The updated carrier selection is immediately reflected in the TMS, with downstream schedules, dock plans, and customer delivery timelines adjusted accordingly.

Step 4: Escalates only when judgment is required

If no compliant carrier is available within the required service window, the agent escalates the exception with a short list of pre-evaluated options such as controlled premium freight or adjusted delivery commitments, enabling logistics leaders to approve the optimal path forward without restarting the sourcing process.

By turning mid-day re-tendering into a continuous optimization loop, agentic AI helps enterprises lower expedited freight costs, improve carrier utilization, and maintain delivery reliability—protecting both margins and customer experience.

3. Supplier risk monitoring and sourcing nudges

Procurement teams operate under constant uncertainty — supplier delays, financial stress, geopolitical instability, and climate-related disruptions can quickly cascade into production stoppages. Yet in many enterprises, supplier risk assessment still relies on static scorecards, periodic audits, and manual reviews that fail to keep pace with real-world volatility.

Agentic AI in supply chain procurement closes this gap by continuously monitoring supplier health and proactively triggering sourcing actions as risk profiles evolve without bypassing governance or commercial controls.

How it works

Step 1: Continuously scans multi-tier supplier signals The agent monitors a broad set of signals, including on-time-in-full (OTIF) performance, shipment delays, quality incidents, credit indicators, and regional risk factors such as weather events or port congestion. Where data is available, it also incorporates Tier-2 and Tier-3 supplier exposure to detect upstream vulnerabilities before they impact production.

Step 2: Scores supplier risk dynamically Instead of relying on quarterly assessments, the agent continuously blends operational, financial, and geopolitical inputs to generate a real-time supplier risk score. Procurement teams gain early visibility into suppliers whose risk profiles are deteriorating—often weeks before traditional processes would surface an issue.

Step 3: Identifies viable alternate sourcing paths When predefined thresholds are crossed, the agent evaluates approved alternate suppliers based on capability fit, lead times, capacity availability, and geographic proximity. Rather than forcing a single switch, it recommends partial reallocations or dual-sourcing strategies to maintain continuity without overloading any one partner.

Step 4: Triggers governed sourcing nudges and controlled actions Based on enterprise policy, the agent issues context-aware nudges to sourcing managers—such as “reduce allocation by 20%,” “initiate dual sourcing,” or “advance safety stock for this component.” For low-risk, pre-approved scenarios, the system can autonomously rebalance allocations within defined limits. Higher-impact decisions are escalated with pre-evaluated options, enabling faster approval without restarting sourcing workflows.

Enterprises such as Western Digital have invested in multi-tier supply chain mapping and continuous risk monitoring to enable near-real-time disruption alerts and automated mitigation workflows. This shift from reactive intervention to proactive risk orchestration helps prevent sudden stockouts, production halts, and downstream customer impact.

4. Adaptive inventory replenishment

Balancing inventory across multiple echelons — plants, distribution centers, and downstream fulfillment locations — is one of the most complex challenges in supply chain management. Static inventory rules often result in excess stock accumulating in one node while shortages emerge elsewhere, tying up working capital and degrading service levels.

Agentic AI in supply chain inventory management addresses this by continuously tuning min/max thresholds, orchestrating replenishment decisions, and executing adjustments in near real time without destabilizing warehouse or production operations.

How it works

Step 1: Consolidates real-time, network-wide visibility The agent integrates data from ERP, planning systems, warehouse operations, and sales channels to track inventory positions and flows across every node. For example, if a distribution center in Chicago is running low on fast-moving SKUs while another facility in Dallas is carrying excess stock, the system detects the imbalance immediately.

Step 2: Dynamically adjusts min/max thresholds Rather than relying on fixed safety stock formulas, the agent continuously recalibrates minimum and maximum inventory levels based on demand variability, replenishment lead times, service-level targets, capacity constraints, and holding costs. It applies “what-if” logic to evaluate how changes impact fill rates, inventory turns, and working capital exposure.

Step 3: Simulates replenishment scenarios before execution Before updating live parameters, the agent tests alternative replenishment strategies in a simulated environment. This ensures that proposed changes improve service and cost outcomes without introducing operational disruptions such as dock congestion or labor inefficiencies.

Step 4: Executes and monitors replenishment autonomously Once validated, the agent updates inventory policies in the planning or ERP system, triggers inter-facility transfer orders, or initiates supplier replenishment within predefined limits. It continues to monitor inventory behavior to identify emerging risks, such as slow-moving stock, excess aging, or potential stockouts.

Through this continuous sense – decide – act loop, agentic AI helps enterprises prevent stockouts, reduce write-offs, and stabilize working capital. Inventory becomes adaptive rather than reactive, ensuring each warehouse, hub, and fulfillment node holds the right inventory at the right time.

💡Did you know

Industry analysts, including Gartner, point to agentic AI as a key enabler of autonomous decision-making across logistics functions — from warehouse orchestration to last-mile execution —unlocking more resilient and responsive supply chains.

5. Warehouse slotting, waves and labor orchestration

Warehouses are under constant pressure to meet aggressive service-level targets while operating with finite labor, space, and time. Static slotting layouts and rigid pick-wave schedules may work under stable conditions, but they often break down during demand spikes, promotions, or channel shifts, leading to congestion, slower picks, and missed dispatch windows.

Agentic AI improves adaptability here by dynamically orchestrating slotting strategies, pick waves, and labor deployment within operational and safety guardrails.

How it works

Step 1: Continuously monitors warehouse execution signals The agent ingests real-time data from the Warehouse Management System (WMS), including order inflow patterns, SKU velocity, equipment availability, labor capacity, and zone-level throughput. For example, if a surge in e-commerce orders shifts demand toward smaller, high-velocity items, the system detects the change early and flags opportunities to rebalance execution priorities.

Step 2: Drives demand-aware slotting adjustments Rather than constantly reshuffling the floor, the agent identifies when and where re-slotting will deliver the highest impact. High-turnover SKUs are prioritized for placement closer to pick faces or high-throughput zones during planned re-slotting windows, reducing travel time and improving pick rates without disrupting active operations.

Step 3: Orchestrates pick waves and labor allocation

The agent dynamically groups orders into optimized waves or enables waveless execution where supported, balancing workload across zones and shifts. Within predefined skill, safety, and labor constraints, it recommends or triggers task reallocation between picking, packing, staging, and dispatch to prevent bottlenecks and idle time.

Step 4: Stabilizes execution during peak periods During peak operations, the agent intentionally locks slotting layouts and picking logic to preserve throughput and avoid mid-shift disruption. Once demand normalizes, it resumes continuous optimization to restore efficiency and rebalance the warehouse.

6. Real-time exception and disruption playbooks

Modern supply chains operate in a near-constant state of disruption — port congestion, labor strikes, extreme weather events, and geopolitical shifts are no longer rare outliers. Yet many organizations still rely on static contingency plans that take hours to activate and depend heavily on manual coordination across teams.

Agentic AI in supply chain operations replaces this reactive model with dynamic, reasoning-based disruption playbooks that can detect issues early, select the right response, and execute recovery actions autonomously within defined governance boundaries.

How it works

Step 1: Detects meaningful anomalies across the network The agent continuously monitors execution signals across transportation feeds, weather systems, customs and port data, supplier updates, and partner platforms. Rather than reacting to every alert, it identifies material deviations such as sustained delays, capacity shutdowns, or cascading ETA risks that cross predefined impact thresholds.

For example, when a storm forces the closure of a major port, the system immediately maps all affected shipments, suppliers, and downstream customer orders.

Step 2: Activates predefined resilience playbooks Each disruption category — port closures, labor strikes, border delays, or capacity shortages —has a corresponding playbook configured by supply chain, procurement, finance, and customer service leaders. Once triggered, the agent initiates the relevant response options, such as rerouting shipments, switching carriers, reallocating inventory, or adjusting production sequences.

Step 3: Simulates responses and selects the optimal path Before execution, the agent runs rapid, bounded simulations to evaluate trade-offs across cost, lead time, service-level impact, and customer priority. Decisions are optimized based on enterprise rules — for example, protecting tier-one customers or time-sensitive orders over lower-priority commitments.

Step 4: Executes actions with transparent human oversight After validation, the agent updates transport plans, inventory allocations, and delivery promises across systems. It notifies internal teams and external partners with concise, context-rich summaries, while allowing human leaders to override or refine actions when judgment or escalation is required.

By closing the loop between detection, decision, and execution, agentic AI enables enterprises to contain the impact of disruption in minutes rather than hours, protecting service levels, customer trust, and revenue during periods of volatility.

7. Greener routing and carbon-aware lane selection

Sustainability has become a strategic priority in supply chain management, but balancing service levels, freight costs, and carbon reduction targets remains a complex operational challenge. Traditional logistics planning primarily optimizes for time and cost, treating emissions as a reporting metric rather than a decision variable.

Agentic AI in supply chain logistics embeds sustainability directly into execution, continuously optimizing routing and mode selection to reduce emissions without compromising customer commitments.

How it works

Step 1: Estimates carbon impact at the lane and shipment level The agent calculates estimated emissions for each transport lane, mode, and carrier using a combination of distance, load factors, fuel type, and telematics-derived performance data. For example, when planning shipments from a distribution center to retail locations, the system evaluates road, rail, and air options across both carbon intensity and cost-to-serve.

Step 2: Evaluates carbon-versus-service trade-offs Rather than defaulting to the fastest option, the agent simulates how alternate modes or routes affect delivery time, cost, and emissions. If shifting a shipment from air to rail reduces emissions materially while staying within SLA tolerance, the greener option is automatically prioritized.

Step 3: Applies enterprise sustainability guardrails Routing decisions are governed by enterprise-defined sustainability policies such as carbon caps by lane, customer tier, or region. High-emission routes are flagged, and the agent recommends alternative carriers, consolidated shipments, or multimodal combinations that align with both service and ESG objectives.

Step 4: Creates auditable, decision-level emission records Every routing decision includes a traceable emissions estimate, along with distance, transport mode, carrier, and fuel assumptions. This creates a transparent audit trail that supports ESG disclosures, regulatory reporting, and customer-facing sustainability commitments.

By operationalizing carbon awareness at the shipment level, agentic AI turns sustainability from a quarterly reporting exercise into a daily execution discipline, helping you reduce emissions without sacrificing reliability, margins, or customer trust.

8. Order promise, allocation and customer communication

Meeting delivery commitments while managing fluctuating inventory and capacity is one of the most complex—and customer-visible—challenges in supply chain operations. Yet many traditional systems still confirm orders based on partial inventory views, creating downstream backorders, split shipments, and broken promises that erode customer trust.

Agentic AI in supply chain execution resolves this by synchronizing order management, inventory, and logistics signals in real-time, ensuring every customer commitment reflects true network availability and operational constraints.

How it works

Step 1: Verifies real-time inventory and fulfillment capacity

When a customer places an order, the agent evaluates inventory availability across plants, distribution centers, and in-transit stock, alongside warehouse throughput and transportation capacity. For example, if a product is constrained at one fulfillment node but available elsewhere, the agent recommends the optimal fulfillment path based on service levels, cost, and delivery timelines.

Step 2: Applies predictive, policy-driven allocation logic

Rather than allocating inventory on a first-come basis, the agent forecasts near-term demand and applies enterprise allocation rules such as customer tier, contractual commitments, margin impact, and regional priorities. This prevents overcommitment and ensures scarce inventory is reserved for high-impact customers and orders.

Step 3: Automates promise dates and targeted customer updates

Using live transport schedules, warehouse capacity, and execution risk signals, the agent commits realistic delivery dates at order confirmation. If conditions change such as a route disruption or sudden demand surge — the system recalculates promise dates and proactively notifies affected customers with clear, context-aware updates, avoiding surprise failures.

Step 4: Keep service, sales, and planning in sync

All promise updates are pushed simultaneously to the ERP, order management, and customer service or contact center platforms. Sales teams, planners, and support agents work from a single source of truth, enabling consistent messaging and faster exception resolution.

By automating intelligent allocation and customer communication, agentic AI helps you protect delivery commitments, reduce escalations, and build trust, turning supply chain reliability into a competitive advantage rather than a liability.

From smarter supply chains to self-driving ones

Across demand sensing, transport sourcing, inventory orchestration, warehousing, disruption management, sustainability, and customer promise protection, one pattern is clear:

the next frontier in supply chain performance isn’t visibility—it’s decision velocity at scale.

Most enterprises already know what is happening in their supply chain. The real challenge is acting fast enough, consistently enough, and in a way that balances cost, service, risk, and customer expectations—every single day. That’s where agentic AI in supply chain fundamentally changes the game, and precisely the shift Sprinklr AI agents are designed to enable.

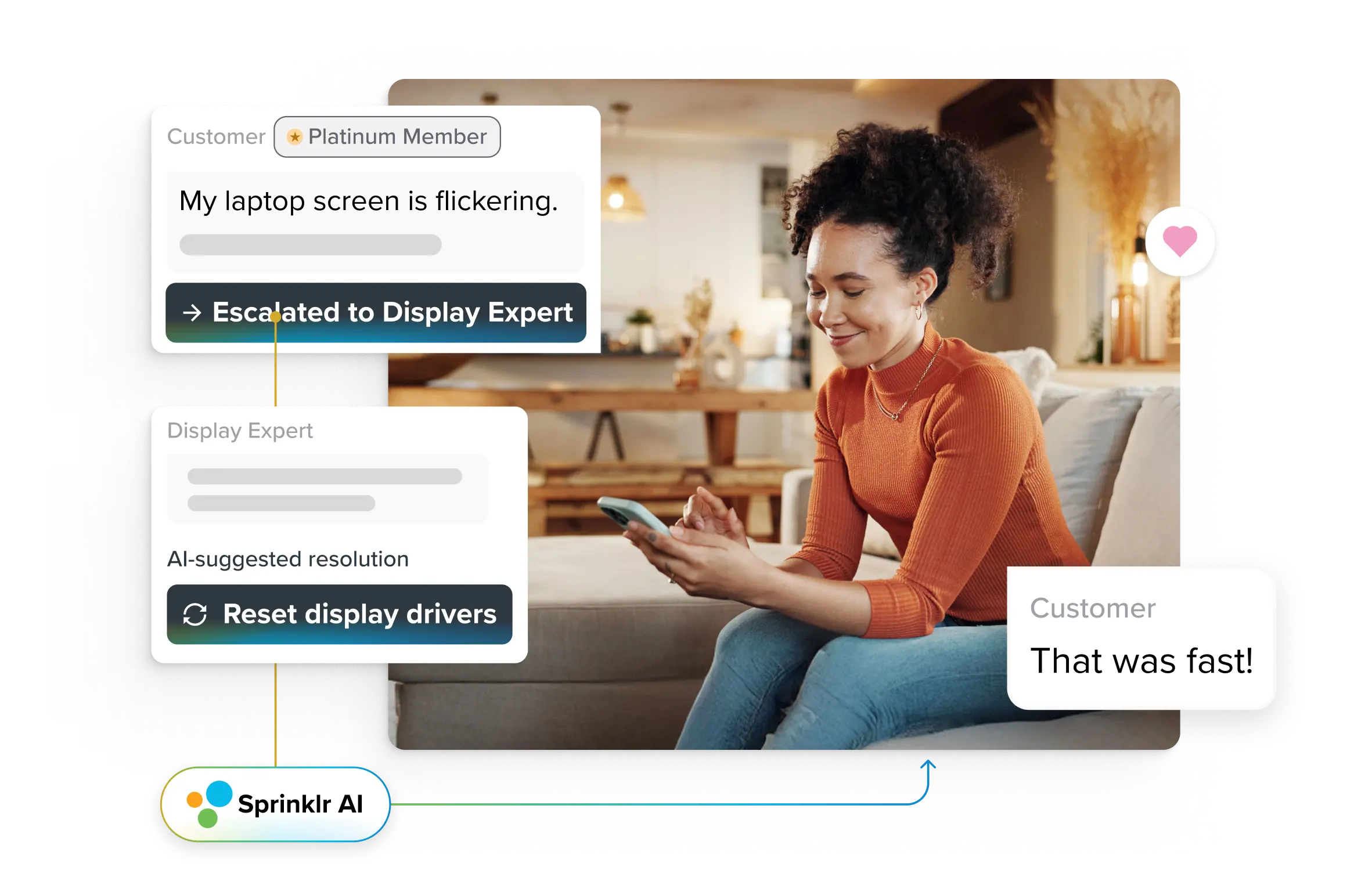

Rather than operating as isolated analytics or automation tools, Sprinklr’s AI agents function as an intelligent execution layer across the supply chain and customer experience. They sense disruptions as they emerge, reason across operational and customer impact, and act autonomously within enterprise-defined guardrails — whether that means rebalancing inventory, rerouting shipments, adjusting delivery promises, or proactively communicating with customers before issues escalate.

Sprinklr AI agents understand how supply chain decisions ripple into the customer experience — missed SLAs, delayed communications, escalations, and churn. By unifying operational signals with customer-facing systems, these agents protect relationships, revenue, and brand trust.

For supply chain, logistics, and customer service leaders, this marks a turning point. The question is no longer whether AI can support decision-making, but whether your organization is ready to let AI execute decisions responsibly, at machine speed, while humans focus on strategy, exceptions, and growth.

Agentic AI doesn’t replace planners, logisticians, or service leaders. It frees them from firefighting. And platforms like Sprinklr are making that shift practical, turning fragmented operations into coordinated, self-healing supply chains that customers can rely on.

If you’re ready to see what that looks like in practice, a walkthrough of Sprinklr AI agents is the natural next step.

Frequently Asked Questions

Traditional AI analyzes data and provides insights or forecasts. Agentic AI takes it a step further by reasoning through context, making informed decisions and acting autonomously. It doesn’t just predict a delay, it finds solutions, reroutes shipments and updates systems while keeping humans informed.

Agentic AI impacts both but delivers faster gains in execution. It detects disruptions, reroutes loads and adjusts routing and inventory in real-time. Once these workflows stabilize, they strengthen planning by providing accurate, live data for continuous improvement.

Use controlled automation. Agentic AI should work within defined thresholds, run sandbox simulations and seek human approval for high-impact actions. These steps prevent unnecessary plan churn and maintain stable operations while AI adapts dynamically.

Industries with high supply complexity or volatility, such as manufacturing, retail, pharmaceuticals and consumer goods, see the fastest impact. These sectors depend on real-time coordination between suppliers, plants and distributors, where agentic AI delivers measurable resilience.

The safest model is a layered integration. Connect agentic AI through APIs or event streams, letting it observe and recommend before executing. Once accuracy is proven, it can act through controlled write-backs to ERP, TMS or WMS systems with full audit logs.